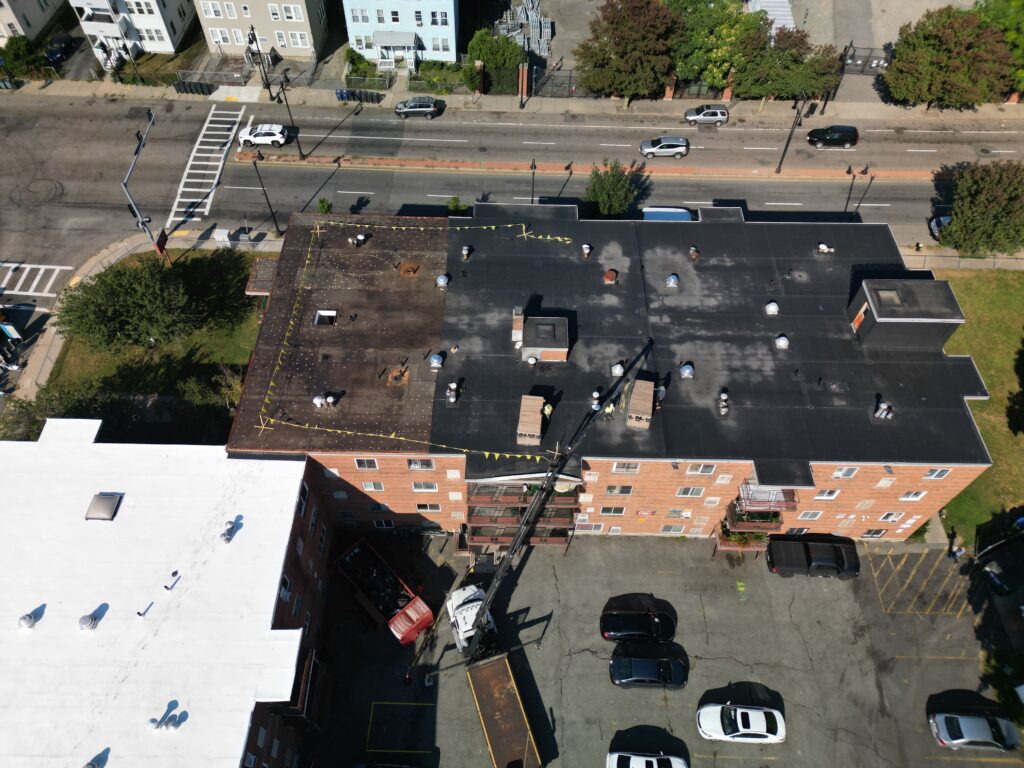

Complex EPDM to PVC Roof Conversion Completed at 790 Hyde Park Ave, Boston

Reading Time: 4 minutesID Flat Roof successfully navigated the complexities of converting an existing EPDM (rubber) roof system to a modern PVC membrane at 790 Hyde Park Ave, Boston, MA 02136.

This project underscores our commitment to delivering high-performance roofing solutions while respecting existing building aesthetics.

Project Overview

The project entailed a complete roofing system upgrade involving:

- Stripping one layer of the existing EPDM roofing material across the entire surface.

- Installing a new layer of durable 60 mil PVC membrane.

- Preserving the original drip edge to maintain the building’s architectural style.

Key Considerations

- Material Conversion: Transitioning from EPDM to PVC required careful surface preparation and compatibility assessments.

- Aesthetic Preservation: Maintaining the existing drip edge was paramount to avoid any alterations to the building’s facade.

- Logistical Efficiency: Utilizing a crane to lift materials to the roof significantly streamlined the project timeline.

- Waste Management: A designated dumpster was conveniently located on the property, facilitating efficient debris removal.

Technical Details

- 60 mil PVC Membrane: Selected for its superior durability, UV resistance, and long-term performance.

- Original Drip Edge Retention: Careful integration of the new PVC membrane with the existing drip edge ensured a seamless and watertight seal.

Project Execution

- EPDM Removal: The existing EPDM layer was carefully removed to provide a clean and stable substrate.

- Surface Preparation: The underlying roof deck was thoroughly inspected and prepared to ensure proper adhesion of the PVC membrane.

- PVC Membrane Installation: The 60 mil PVC membrane was expertly installed using heat-welding techniques to create a seamless, watertight barrier.

- Drip Edge Integration: The new PVC membrane was meticulously integrated with the existing drip edge to ensure a weathertight seal while preserving the building’s original aesthetic.

Benefits for the Property Owner

- Enhanced Durability: Compared to EPDM, the PVC membrane offers superior resistance to weathering, UV degradation, and chemical exposure.

- Improved Aesthetics: Maintaining the original drip edge preserves the building’s architectural integrity and curb appeal.

- Streamlined Project Management: A dumpster’s availability and crane use facilitated efficient waste management and material handling, minimizing disruption to residents.

- Long-Term Value: The PVC roofing system provides a durable, low-maintenance solution that enhances the building’s value and protects its structural integrity.

Conclusion

ID Flat Roof’s meticulous approach to the 790 Hyde Park Ave project showcases our expertise in navigating complex roofing conversions while prioritizing aesthetic considerations. By carefully transitioning from EPDM to PVC and preserving the original drip edge, we delivered a high-performance roofing system that enhances the building’s value and protects it for years. The project took 1 month to complete.

Denis is the driving force behind ID Flat Roof, a leading company in Boston specializing in flat roof repair and installation for over 20 years.

Expertise:

Denis excels in PVC, TPO, EPDM, and rubber roofing. His meticulous approach ensures quality and customer satisfaction.

Innovation:

Denis incorporates cutting-edge solutions like skylights and solar PV roofing.