ID Flat Roof – Flat Roof Repair Company

We Will Make Sure You Forget about Flat Roof Leaks Forever

Experience More Than 23 Years

Lifetime Warranty

We accept credit cards

Financing

ID Flat Roof Corp is a Certified Flat Roof Repair, Replacement, Maintenance, and Installation Contractor in Boston, Massachusetts

A solid roof is the guarantee of your comfort indoors. And it does not matter what premise and housetop type we are discussing. ID Flat Roof is a trustworthy local company that has performed well in Massachusetts for over 20 years.

Our dedicated team makes residential and commercial premises more comfortable and highly protected from changing weather and other external factors with the help of qualitative roofing services.

If you are looking for flat roof repair specialists or installers in your region, do not hesitate to contact us. Our specialists are experienced roofers with an advanced approach to each entrusted project. We undertake necessary measurements, surface inspection, and competent estimations to make your roof repair or replacement experience as pleasant as possible.

ID Flat Roof has completed hundreds of installations and renovations of roofs in the Massachusetts region, offering our clients the best roof solutions in every case. As a result, we have earned a reputation as a reliable ‘near me’ PVC, TPO, EPDM, deck, and rubber roof installer that completes any roofing project.

ID Flat Roof Quality Services

ID Flat Roof is not an average MA-based company with limited services to consider. Our professional crew keeps track of the latest technologies and innovations to provide the best roofing services near me. We are your reliable local contractor, ready to install any roofing construction in the shortest term. Our team of professional roof installers works in Middlesex, Suffolk, Norfolk, Essex, Plymouth, Bristol, Barnstable, and other Massachusetts areas.

We pay personalized attention to each project and offer time-tested flat roof solutions according to the client’s requirements. Our company is just the kind of EPDM, PVC, and rubber roof installers near me that you will recommend to your friends.

One of the most demandable installations in New England people often ask us to assist with is PVC membrane roofs. This roofing material is designed and provided by the leading company in the USA — Roof Systems. Our company is a certified and well-trained contractor with a whole skillset for reliable installation of PVC membranes for your flat and low-pitched roofs in MA.

ID Flat Roof is licensed to implement other roofing solutions for residential and commercial premises like dance decks, green roofs, PVC roof panels, rubber roof installation, etc.

Full Range of Flat Roof Repair in Boston, Massachusetts

Roof installation: Our specialists mount any roofs from scratch, including the structure of the frame and underlayment, and finish with insulation and covering materials. We design and install roofs on residential and commercial buildings, porches, extensions, and sheds.

Please call +1 (617) 299-0291 for a FREE phone consultation or Request an Estimate Today

Service Area

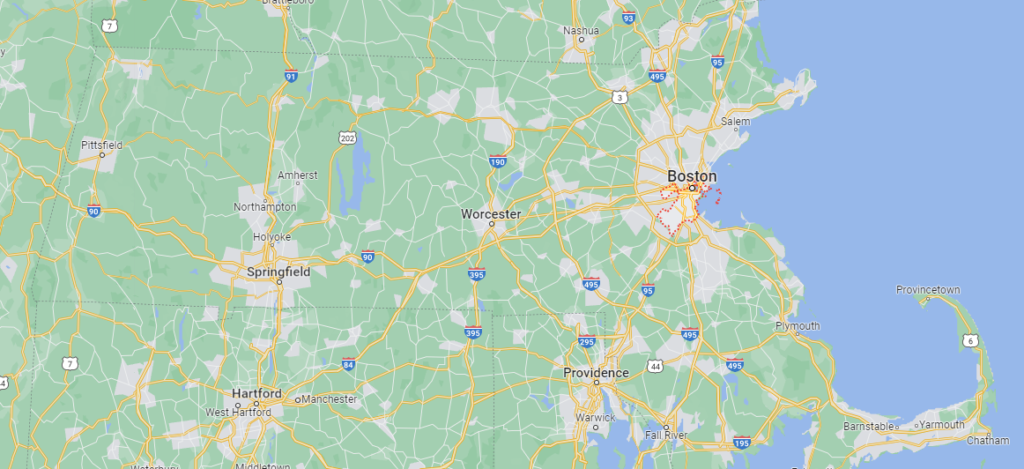

Not sure if your property belongs to the ID Flat Roof service area? Just use the interactive map. If your address appears in the blue zone, it is in our service area.

More About Modern Roofing Solutions

Compared with other roof companies, we always check for updates in techniques and construction solutions to make your homes even more convenient and eye-catching. A perfect PVC membrane roof can complement your exterior and protect your building from severe winds, stormy weather, water leaks, and other unpleasant situations.

Roof Systems provides a lifetime warranty for residential materials and 30 years for commercial constructional elements, while our company guarantees a 10-year workmanship warranty!

It is worth noting that traditional roofing techniques are also available for our clients. Citizens of the New England locations (in Massachusetts and especially – Boston) can count on the high-grade installation of tar, rubber roll roofs, metal shingles, copper roofing installations, and other variants required for their projects.

Among the most innovative solutions we are ready to provide are the following:

- Skylight — open, vented, and permanent skylight installations;

- Deck Shield installation — the perfect variant for balconies, additions, etc.;

- Solar PV roofing options — we can install solar panels to allow you to get renewable energy all the yearlong;

- Dancing decks — solid installations with improved anti-foot properties for your flat roofs.

If you want approved services, contact ID Flat Roof — the best roofing company near me, with a stable local presence throughout Massachusetts and Boston.

Why Particularly Us?

We do not limit our customers in their capabilities regarding premium roofing services. You get a perfect warranted result at affordable prices. Additionally, our roof installers offer high-quality replacement of housetops and emergency roof repairs near me (locally). Contact our managers to place the order or ask any questions concerning your project! A significantly improved exterior starts with a sustainable installation!

Please call +1 (617) 299-0291 for a FREE phone consultation or Request an Estimate Today

What People Say About ID Flat Roof

I am a property manager, always looking for reliable contractors. I can say that ID Flat Roof has earned my trust for a long time. The team always shows exceptional professionalism, from a simple consultation to completing all construction work. I can honestly recommend them.

We have known ID Flat Roof for a long time. They never disappoint! Their roofing services are top-notch, and their customer service is very friendly. They are probably the only best in Newton who provide perfect roofing services for reasonable prices.

It took me a long time to choose companies that I could entrust with my roof repairs. Eventually, I came across ID Flat Roof. And I don’t regret anything! The team comprises true professionals and sincere and responsive people. I was completely satisfied with installing the PVC roofing system on my home. I will recommend these guys to my friends if they need such services.

Love ID Flat Roof Company

ID Flat Roof replaced two flat old leaky tar roofs with PVC membrane roofs 10+ years ago, and the roofs still seem brand-new, despite sun beating down on them in the summer and heavy snow loads in the winter. The hot welding technique they use for seams is awesome – never any problem with leaks or anything else. Plus, they added a slight slope to the roofs so that they now drain properly, and they also did railing posts and flashing so that the railings could be installed properly. They are very professional and skilled, and they stand behind their work with an excellent guarantee.

Latest Posts:

- PVC Roof Installation: All You Need to Know About PVC Roofs

- Top Choices for Affordable Roofing Near Me: Your Guide to Budget-Friendly Roof Services

- Top Commercial Roofing Companies Near Me: Quality Services In Your Area

- Residential Roofing Services: All You Need to Know about Your Roof

- Get Your Accurate Cost Estimate to Replace Roof in 2024: Essential Guide