PVC Roofing Membrane Complete Guide: Pros, Cons, and Tips

Reading Time: 10 minutesPVC roofing membranes have become a popular roofing material for residential property (especially with flat or low slope roofs). Moreover, it is believed to be the practical choice for all types of warehouses, office and shopping centers, and industrial and municipal facilities all over the USA. Its stable popularity lies in the well-known advantages of trending material. Let’s explore the history of PVC membranes and their advantages over traditional alternatives. Let’s explore different types of membranes, get tips for choosing the right one, and learn about their limitations and installation features.

A Brief History of PVC Roofing Membranes

Even though PVC is considered a modern roofing covering, Polyvinyl Chloride roofing membranes were first introduced in the 1960s. It was a modern alternative to traditional roofing solutions such as asphalt, metal, tar, etc. Today, little has changed.

PVC roofing systems are part of the broader category of single-ply systems, which have evolved significantly since their introduction in the 1960s.

Initially installed on large-scale commercial roofs, this material gained popularity for its lightweight, waterproof, and other significant properties for US business owners. By the 1980s, PVC membranes became more widely used, especially in Europe and North America. Nowadays, you can see them worldwide—or even in your neighborhood.

PVC was used primarily in projects where maximum protection was necessary, especially against leaks, including when installing flat roofs of cottages, townhouses, and country houses. Today, anti-leak protection is the first thing that comes to mind when discussing PVC or any other synthetic membrane, like TPO or EPDM.

What is a PVC Roofing System?

A PVC roofing system is a type of single-ply roofing system that utilizes a polyvinyl chloride (PVC) membrane as the primary waterproofing layer. Known for its durability, flexibility, and resistance to chemicals, grease, and fire, PVC roofing systems are famous for commercial and industrial buildings. However, they are also suitable for residential roofs, mainly flat or low-slope designs.

A typical PVC roofing system comprises several key components: the PVC membrane, insulation, and a substrate. The membrane itself can be mechanically attached or fully adhered to the roof deck, depending on the specific requirements of the building and the preferences of the installer. This versatility makes PVC roofing systems an excellent option for various applications, providing reliable protection and performance.

How Membranes Are Better than Asphalt and Metal

Let’s start with durability. PVC is durable. If inspected and maintained correctly, average PVC roofs have longer lifespans than natural materials, often lasting up to 30 years—and even 50 in some cases. Unlike traditional materials like asphalt, which can degrade under extreme weather conditions, high-quality PVC can be more resistant to UV rays, dozens of chemicals, and punctures. Additionally, some PVC membranes come with fleece backing, which enhances durability by providing extra resistance to punctures and physical damage.

How can you save hundreds of dollars with PVC? Here is a life hack. If you spend a lot of money on air conditioning, another reason to choose PVC is its proven energy efficiency. According to observations, PVC roofing membrane is often white or light-colored. It reflects sunlight (dark materials such as asphalt or rubber absorb much more sun rays, heating the whole building). This makes light membranes more energy-efficient. As a result, it lets the building owner save money by using electricity wisely.

No leaks. As mentioned above, synthetic membranes’ fundamental benefits are their waterproofing abilities. PVC membranes offer probably the most reliable waterproofing (compared with traditional options). The reason is their hot-welded seamless installation process. Traditional materials often involve multiple layers or seams. They can become weak points for leaks over time. Еhis is not something you want to see on your roof.

PVC can be more fire-resistant than other time-tested and widely used roofing systems, depending on the membrane type. This makes it safer than more flammable materials like wood or bitumen, although PVC is not entirely fire-resistant.

Eco-Standards. Some PVC roofing membranes are produced to be recyclable. According to industry standards, this synthetic product can be reused after 20-30 years or at the end of its declared life cycle. It makes them a more sustainable option than materials that produce significant waste. However, PVC is synthetic, after all.

Types and Varieties

PVC membrane roofing materials, available on the US market nowadays, come in various forms. Choosing the right one depends on various factors.

- Roof slope.

- Climate.

- Architecture.

- Building specialization.

- Industry requirements.

There are several types of materials:

- Reinforced.

- Non-reinforced.

- With fleece.

- PVC-P.

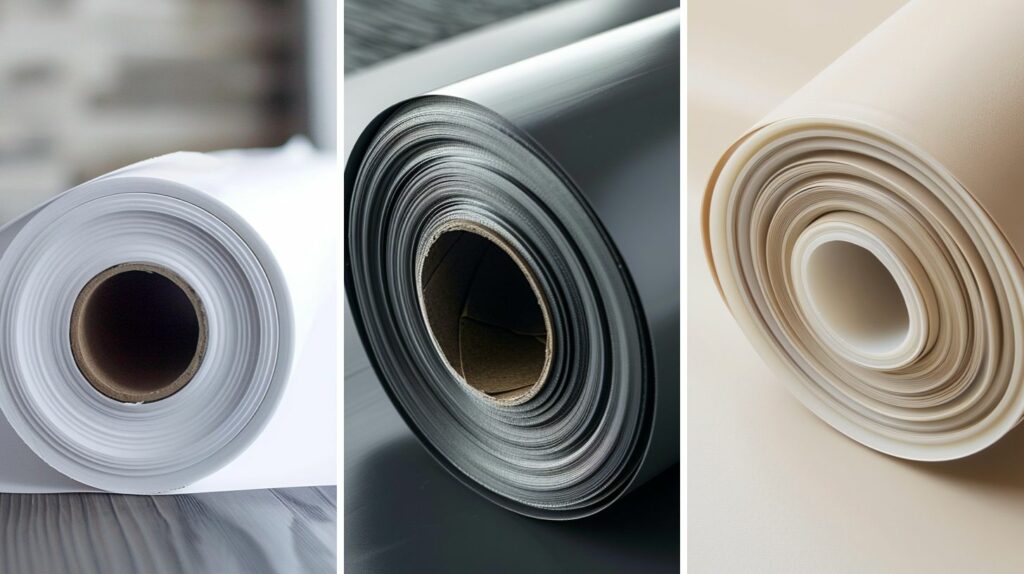

Reinforced PVC Roll

Non-reinforced PVC roll

PVC roll with fleece

PVC-P

A reinforced and thick membrane is a popular but not universal choice. Some additives in the structure (commonly polyester or fiberglass mesh) can improve performance. They provide added strength and durability. While these membranes can be more expensive, they are supposed to be a practical choice for large-area roofs with heavy foot traffic or regions with harsh weather, heavy rains, and snowfalls.

Non-reinforced PVC. These solutions are more affordable and more flexible because they don’t contain polyester or fiberglass, which makes them easier to work with. If you are looking for an affordable material for a residential roof with no foot traffic, then a non-reinforced membrane may be the most suitable choice.

Fleece-backed PVC membrane is a more common option for some commercial projects. These membranes have a layer of fleece on one of the sides (typically on the underside). They offer enhanced insulation and additional protection against physical impact or even punctures. Such materials are well-suited for installation over rough or uneven surfaces.

PVC-P membranes are not the most widely known option. However, they contain plasticizers for added flexibility, making them the best choice for roofs that experience frequent temperature fluctuations.

Choosing PVC Membranes: Tips for Business and Homeowners

There are 10-15 commonly used roofs that differ in shape, architectural features, roof pitch, etc. For flat or low-slope roofs (minimal angle of inclination is 1:80 or 0.72), PVC membranes are a superior choice due to their anti-leaking capabilities. In residential applications, they work well on modern, minimalist homes. In commercial real estate, they are often used on buildings with large-scale roofs, like a warehouse or office building.

The market offers membranes of different thicknesses. From 40 to 90. One of the most popular is a PVC membrane with a thickness of 60 mils.

PVC membrane roofs perform exceptionally well in hot and warm climates thanks to their reflective features. In colder climates, reinforced or fleece-backed membranes provide extra insulation and protection from extreme temperatures.

Another feature you should consider is longevity. Commercial properties, which often prioritize the long-term service life of roofing coverings, benefit from thicker, reinforced PVC membranes. These membranes can withstand years of exposure to the elements without frequent repairs.

As you might guess, different membranes cost differently, and some can cost much more. While PVC roofing may initially be more expensive than asphalt or tar, its benefits make it a cost-effective solution in the long run, especially for projects with large-scale and flat roof surfaces.

Cost and Budgeting for PVC Roofing

| Job | Size (sqft) | Labour |

|---|---|---|

| Porch | 54 | 1 day |

| Single Garage | 194 | 1 day |

| Double Garage | 388 | 1-2 days |

| Extension | 484 | 2-3 days |

Several factors can influence the overall cost when budgeting for a PVC roofing project. These include the roof’s size, the PVC membrane’s thickness, and the chosen installation method. On average, PVC roofing ranges from $12 to $20 per square foot, making it a competitive option among single-ply roofing systems.

While the initial investment may be higher than traditional materials like asphalt shingles, building owners should consider the long-term benefits of PVC roofing. Its durability and low maintenance requirements can significantly save costs over time. With proper installation and regular maintenance, a PVC roof can last for 25 years or more, making it a cost-effective solution in the long run.

Limitations of PVC Roofing Systems

Despite the significant list of mentioned advantages, PVC membranes have some limitations.

- Cost.

- Thermal expansion.

- Minimalistic Appearance.

Money-consuming. The upfront cost of PVC membranes is higher than that of traditional materials like asphalt or metal. However, this is often offset by lower or even zero maintenance. As mentioned above, light membranes can also be energy-efficient and essential in sunny regions.

Expansion. Another disadvantage you should consider while designing PVC membrane roofs is thermal expansion. PVC can change geometric shape under temperature changes, potentially causing seams to weaken or crack over time. Professional installation, proper membrane type selection, and expansion joints can mitigate this risk.

Also, PVC membranes typically come in neutral colors like white, gray, or beige. If you’re looking for a more traditional or decorative roof, PVC may not offer the variety of styles found in shingles or tiles.

Although PVC is recyclable, its production involves chemicals that some environmentalists consider harmful. Alternative membranes made from thermoplastic polyolefin (so-called TPO) are sometimes considered more eco-friendly. However, TPO also has many drawbacks.

Installation Features: Frame, Base, and Insulation

1. Roof Frame

PVC membranes are lighter than tile and metal, so they can be mounted on both built-from-scratch and existing renovated roofs without adding significant load to the building structure and roof frame. However, the roof frame must be solid enough to support new material and insulation and withstand potential foot traffic during installation.

2. Base

According to expert recommendations, the polyvinyl chloride membrane (regardless of thickness) must be applied over a smooth, clean surface, such as a concrete or wooden base. Debris, sharp objects, or uneven surfaces can damage the PVC material and compromise its waterproofing abilities.

3. Insulation

Not only the comfort of living but also the size of long-term heating costs depends on the thermal insulation of the roof. PIR or XPS insulation materials are often used under PVC membranes to provide proper insulation and reduce natural heat loss, even in cold months.

4. Attachment

PVC membranes can be attached in three ways. With unique mechanical fasteners. With adhesive. Or using ballast (usually gravel or pavers). Each method has advantages and limitations depending on the roof type and area, roof frame structure, and local weather conditions.

Maintenance of PVC Roofing Membranes

PVC membranes (if we are talking about modern products available on the US market) are relatively low-maintenance. Compared to traditional materials. Routine inspections should be done once or twice a season or after heavy rains to ensure the membrane remains free from leaks and damage, such as punctures or seam separation. If necessary, repairs are relatively simple and can be performed by applying heat-welded patches to damaged areas.

Environmental Impact of PVC Roofing

PVC roofing stands out for its relatively low environmental impact compared to other roofing materials. One key advantage is that PVC is recyclable, and many manufacturers offer recycling programs for their products. This means that a PVC roof can be repurposed at the end of its life cycle rather than ending up in a landfill.

Additionally, PVC roofing can contribute to energy efficiency. Many PVC membranes come with reflective coatings that help reduce heat absorption, lowering cooling costs in warm climates. However, it’s important to note that PVC production involves chemicals that can be harmful if not managed properly. Building owners should seek out manufacturers that prioritize sustainability and environmental responsibility to mitigate these concerns.

Typical Applications for PVC Roofing

PVC roofing is widely used across various types of buildings due to its versatility and superior resistance properties. It is commonly found in the commercial and industrial sectors in office buildings, warehouses, and factories. Its ability to withstand chemical, grease, and fire exposure makes it an ideal choice for restaurants, hospitals, and laboratories.

PVC roofing is particularly well-suited for flat or low-slope roofs in residential settings. Its flexibility allows it to be easily formed and shaped around roof features such as vents and skylights, making it a practical option for homes with complex roof designs. For commercial or residential applications, PVC roofing provides reliable protection and performance.

Warranties and Guarantees for PVC Roofing

When investing in a PVC roofing system, it’s crucial to understand the warranties and guarantees offered by manufacturers. Typically, these warranties range from 10 to 30 years or more and cover defects in materials and workmanship, leaks, and other performance issues.

Building owners should carefully review the warranty terms to ensure they are getting comprehensive coverage. Choosing manufacturers that offer robust customer support and service is also beneficial. Some manufacturers may provide extended warranties or maintenance programs, which can help extend the roof’s life and provide additional peace of mind.

By considering these factors, building owners can make an informed decision and ensure the protection of their investment in a PVC roofing system for years.

Five Reasons to Take a Closer Look at PVC Membranes

The roofing industry offers a dozen technologies and even more varieties of materials, from natural to synthetic. Each material has a stated service life of 5 to 50 years and a manufacturer’s warranty. Regarding PVC, it depends on the membrane type and brand you choose and the roofing company’s policy. However, the average lifespan of PVC is up to 30 years.

Roofing is a long-term investment. If you choose PVC membranes, your investment can yield profit. For example, a roof that does not heat up as much in the summer months will reduce your electricity bill. Imagine how much you will save over 30 years.

No leaks – no problems. Professionally done seamless installation and top waterproofing make PVC membranes ideal for flat roofs prone to water pooling.

Each material has natural enemies and weaknesses. For example, wooden roofing can rot or attract termites, while metal roofing rusts. Of course, PVC also has its drawbacks. However, this material is not subject to corrosion or decay. It tolerates temperature changes and moderate physical impact.

Any roof needs periodic maintenance and minor repairs. With regular inspections and minor repairs (with special patches or self-adhesive tapes), PVC membranes require less upkeep than time-tested, out-of-date roofing materials like asphalt or metal.

Check other PVC porject by ID Flat Roof

High-Quality PVC Roof Installation at 23 St Marys Ct, Brookline, MA

Comprehensive Roofing Renovation at 7 Craigie Circle, Cambridge, MA

Efficient White PVC Roof Installation at 54 Solaris Rd, Hyde Park, MA

PVC Roof is the Best Roof

PVC roofing membranes have transformed modern roofing solutions. They offer significant benefits in terms of durability, energy efficiency, and ease of installation. While they have some limitations, their advantages make them ideal for residential real estate and commercial properties, particularly in states with extreme weather conditions.

Whether considering a new roof for a private home or a large-scale commercial project, PVC membranes provide a cost-effective, sustainable, trouble-free, and reliable solution for long-lasting performance.

Denis is the driving force behind ID Flat Roof, a leading company in Boston specializing in flat roof repair and installation for over 20 years.

Expertise:

Denis excels in PVC, TPO, EPDM, and rubber roofing. His meticulous approach ensures quality and customer satisfaction.

Innovation:

Denis incorporates cutting-edge solutions like skylights and solar PV roofing.