Unlocking the Potential of Corrugated Plastic Roofing: Durability Meets Modern Design

Reading Time: 5 minutesCorrugated plastic roofing has numerous advantages. It is durable and resistant to many deteriorating factors, such as UV light, corrosion, extreme temperatures, or high wind. Plus, its structure creates a natural path for water to flow down, preventing moisture from accumulating.

Yet, the material’s transparency determines its limited usability and other potential shortcomings. For instance, its snow load can be insufficient for severe winters.

Plastic Roofing: Variety of Modern Solutions

Contemporary technology introduced people to multiple materials that can substitute wood, metal, or other traditional roofing solutions. Corrugated plastic is one of the most effective options for compensating for the disadvantages of natural roofs.

Two factors pave the way to understanding the essence of corrugated plastic roofing. First, its composition is primarily plastic, and second, it features a corrugated design. These aspects determine the inherent flaws and merits of constructing corrugated plastic roofing systems.

Shapes & Forms

| Flat (Solid) Roofing Sheets | Corrugated Roofing Sheets |

| The surface of the panel sheet is flat. Hence, the construction is easier to install and repair due to the absence of complex shapes. | The panel sheet has repetitive folds in rectangular or waveforms. As a result, the structure exhibits enhanced durability. Moreover, folds provide a natural slope for water to stream down. |

Materials

| PVC | PC | Acrylic Plastic/Plexiglass |

| Thermoplastic | ||

| Polyvinyl Chloride is a polymer of vinyl chloride monomer (chloride groups). | Polycarbonate appears from the reaction between Bisphenol A and phosgene (carbonate groups). | Polyacrylate is a polymer of methyl methacrylate (PMMA). |

| Flat/Corrugated | Flat/Corrugated | Flat |

| Both materials are durable and resilient. However, polycarbonate demonstrates advanced longevity, insulation properties, and resistance to outside impact. Yet, it’s easier to leave a mark on its surface. Plus, PVC is more affordable. | PMMA is more transparent and resembles glass. It is the least expensive of the plastic roofing solutions. It successfully resists scratches but is easy to crack. | |

A Note to Remember:

Acrylic roofing can be a feasible option for places that require transparency or light transmittance. Still, these panels exist only in a flat form. Therefore, ‘corrugated plastic roofing’ only refers to PVC or polycarbonate sheets.

Corrugated Plastic Roofing Special Features

Perfect roofing combines the desired ease of installation, durability, visual aesthetics, and price. Hence, analyzing these parameters helps you decide whether corrugated plastic roofing matches your requirements.

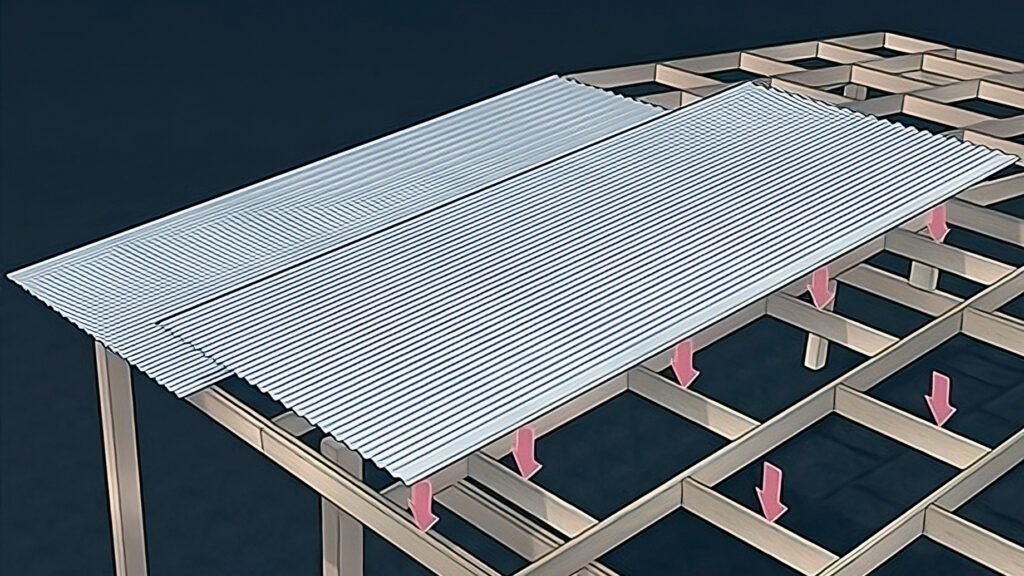

Ease of Installation

Generally, corrugated plastic roofing installation doesn’t need specific knowledge or professional equipment. However, polycarbonate can pose more of a challenge in this respect because it can require advanced skills and special tools. Still, both materials are suitable for DIY projects.

Plastic is lightweight. Therefore, on the one hand, it makes the installation and replacement processes easier. Yet, on the other hand, it limits the panel’s thickness, reducing its capacity to endure heavy loads.

Polycarbonate beats PVC in this respect because it intends to resist shattering. Bulletproof glass is a perfect illustration of polycarbonate’s resilience to outside impact. However, its ability to withstand pressure for a long time has limits. It can fail you during intense snowfalls.

Safety First:

Of course, you will need at least a little experience in construction to accomplish the task. Furthermore, this job entails spending considerable time working at heights. Thus, it would be best if you always took safety precautions.

Resilience

Corrugated plastic is almost unbeatable to outside impact. Plus, it’s immune to traditional enemies of natural materials, including moisture, fire, corrosion, moss, mold, rust, rot, and insects.

| Weather conditions (rain 🌧️, snow ❄️, extreme temperatures 🌡️, high winds 💨, etc.) | UV radiation ☀️ | Fire & lightning strikes ⚡🔥 | Outside impact (scratches, shattering, pressure, debris, etc.) 🛠️ | Natural intruders (vegetation, pests, bugs, etc.) 🌿🐜 |

| ✔️ | ✔️ | ✔️ | ✔️ | ✔️ |

PVC and polycarbonate suffer from scratches and have trouble withstanding pressure or extreme temperatures for an extended period. Still, PC displays advanced resilience, especially in UV rays or cold weather. Additionally, multiple covers for enhancing or stabilizing the capabilities of materials are available.

Longevity

Corrugated plastic roofing, known for its durability, can last approximately 20–30 years due to its resistance to almost all deteriorating factors. Naturally, signs of decay in corrugated plastic roofing appear within the first ten years. However, with correct installation and proper care, the lifespan of this roofing material can be easily prolonged to its maximum potential.

Appearance

PVC and PC are UV-resistant. However, the latter is superior in this respect. As a result, PVC panels are more likely to become less transparent or turn yellow with time.

Plus, polycarbonate offers more versatility in terms of opacity. You can select transparent, translucent, or opaque panels.

Word of Advice:

Transparent corrugated plastic panels are only 0.8 mm, 1.1 mm, or 1.3 mm thick. If you plan to install the roof over the premises that will experience severe conditions, you should search for less transparent options.

Sheets with 4, 6, or 10 mm thickness will serve you longer, especially if you opt for the twin-walled panels. They also won’t upset you with discoloration.

Sustainability

Corrugated plastic roofing is eco-friendly and completely recyclable. Therefore, you won’t feel guilty for sending it to a landfill after removal.

Insulation

This trait shows the essential difference between PVC and PC. The first one isn’t thick enough to provide proper insulation. Meanwhile, the latter allows you to take advantage of ‘the greenhouse effect’ and make a place energy-efficient.

Price

The contemporary economy is dramatically volatile. In a Home Depot online store, prices for plastic roofing can fluctuate drastically. For instance, you can choose an affordable $10 option or opt for an expensive one and pay $500. Generally, PVC is an affordable option, while polycarbonate roof panels are more expensive.

Potential of Corrugated Roofing in Boston, Massachusetts

Boston can surprise its citizens with a vast range of weather conditions. Indeed, it can pour substantial amounts of precipitation on the streets. Yet, bright sunshine is also a frequent visitor in this area.

As a result, you can install a transparent roof and enjoy its light transmittance ability to the fullest. Corrugated plastic roofing will benefit you the most if you put it over non-residential spaces:

- Carports, porches, or walkways;

- Canopy, pergola, or gazebo;

- Greenhouse, outdoor garden, pavilion, or chicken coops.

Professional Tip:

If you intend to grow plants in your greenhouse during winter, use 4-10 mm polycarbonate panels. Otherwise, the premise won’t generate enough insulation capacity.

Overlay4

Concluding Thoughts on Corrugated Plastic Roofing

Plastic roofing is durable. It is also lightweight and requires almost no maintenance. The corrugated shape boosts its strength and generates a natural drainage for moisture.

However, in Boston, Massachusetts, snowfalls can be intense. Therefore, purchase the thickest panel sheets if you intend to utilize corrugated plastic for your roofing project. Otherwise, there is a peril that the structure will collapse because of heavy snow load.

To ensure safety and durability, it’s advisable to consult professionals who can efficiently and swiftly install the roof tailored to withstand such weather conditions.

Denis is the driving force behind ID Flat Roof, a leading company in Boston specializing in flat roof repair and installation for over 20 years.

Expertise:

Denis excels in PVC, TPO, EPDM, and rubber roofing. His meticulous approach ensures quality and customer satisfaction.

Innovation:

Denis incorporates cutting-edge solutions like skylights and solar PV roofing.