Roof Membrane: Advantages and Field of Application

Reading Time: 6 minutesRoof Membrane is a high-demand material more suitable and economical than alternative metal, wood, slate, and other available roofing solutions.

The percentage of membranes in the US market grows yearly, reaching 85% in the commercial roofing category. In addition, you will often see such membranes as PVC and TPO on residential estates, garages, and outbuildings roofs.

Benefits of Using a Roof Membrane and Its Practical Applications

The membrane roofing category includes time-tested solutions (like modified bitumen) and modern technologies (like EPDM, PVC, and TPO membranes).

The scope of the technology is flat and low-slope commercial and residential roofs with a minimum slope angle of 1/2”-1/4” per foot. Such slope guarantees positive drainage as well as prevents the appearance of massive ponds.

Membrane materials are the best choice for large commercial buildings, occupied roofs (restaurants, patios), and residential buildings with terraces.

To add, professionally designed and properly installed membrane roofing has some distinct pros:

- membrane roof has an outstanding level of anti-leaking protection;

- membranes exist for roofing surfaces with a minimal angle of inclination;

- a fully adhered membrane is highly resistant to strong winds and protected from roof uplift;

- membranes are resilient (not all of them);

- membranes are light compared to metal and slate;

- fast and easy installation;

- market availability of membranes of different thicknesses and colors, including energy-efficient coverings.

The specific list of advantages, expected lifespan, and roof appearance depends on the chosen material.

Types of Flat Roof Membranes: Built-Up, Synthetic Rubber, and Single-ply Options

US Roofers commonly work with several types of membrane roofing systems. Membranes differ in raw materials, installation method, ‘roofing pie’, and frame requirements.

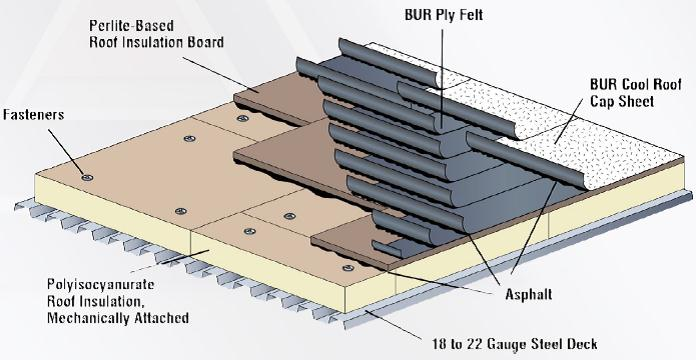

1. Built-up Roofing Membranes (BUR) or Tar and Gravel Roofs. Old-school roofing membrane mounts on American buildings for many decades. BUR’s base is several layers of asphalt sheets (with optional aggregate surfacing and reinforcement) laying on an insulation foundation.

The service life of professionally installed and fully adhered BUR membranes is 10 to 30 years. However, this technology is not environmentally friendly. In addition, chemical compounds dangerous to humans are present during the installation. The peak of the popularity of this technology came in the last century.

2. Polymer Modified Bitumen Membrane (one more specific term is Modified Bitumen). This rolled-up membrane consists of reinforced fabric with bitumen and polymer components.

Usually, roofers use one of the time-tested modified bitumen membranes. The first is Styrene-butadiene-styrene (SBS), and the other is Atactic polypropylene (the short term is APP).

Although installing an SBS or APP membrane is easier and faster than a built-up roof, you must install at least two or even three layers of material for a better seal.

3. Ethylene Propylene Diene Monomer (usually shortened to EPDM or ‘rubber roof’ for simplicity). Most EPDM products are petroleum-based, 45-60 mil thick single-ply roof membranes.

Synthetic rubber roofing is a technology that has existed for decades and is especially popular in commercial construction. Installation of EPDM membranes is more accessible, but this material is not ecological-friendly. In addition, there are health concerns surrounding EPDM membrane roof system use.

4. Polyvinyl Chloride membrane roofs (abbreviated name – PVC roofs). PVC roof membranes are reinforced single-layer membranes.

One of the main pros of the material is its immunity to bacterial growth. It is durable. To add, PVC is a chemically stable material, but it can still be hazardous to people and the environment.

The thickness of PVC membranes can be different. Some manufacturers offer up to 90 mil thick membranes, but 40-60 mil material is the most common format. The popular colors of PVC are white, light gray, and so on because light-colored membranes heat up less in summer.

5. Thermoplastic Polyolefin Membranes (TPO membranes). TPO is a more modern material, unlike the EPDM, rubber, and PVC membranes. TPO membranes are watertight (the seams are welded during installation). In addition, most TPO membranes are recyclable and more ecologically friendly than the materials mentioned above.

Less popular technologies include KEE roofing, Spray Polyurethane Foam (SPF), and Liquid Membrane Roofing.

Roofers choose appropriate roofing membranes considering many factors like the cost of material and installation, the architectural features and area of the building, the type of roof underlayment and insulation, the method of installation, and the compatibility of the membrane with other materials.

Roof Membrane Installation Tips

The mounting method depends on the chosen material. If you choose the wrong installation method, the roof’s life will be minimal.

In addition, the installation of a roof membrane requires compliance with safety regulations. For example, if we are talking about rolled modified bitumen roofs, they are usually mounted on a base heated with a torch. BUR installation usually involves the use of hot bitumen. It can be dangerous and traumatic as well.

As mentioned above, installing most roof membranes involves environmental, health, and fire hazards. Therefore, it is better to entrust the installation of the membrane roofing covering to professionals with the appropriate licenses, equipment, and insurance.

Let’s talk in more detail about the features of mounting single-ply membranes. Usually, you’ll find them as large sheets of material hermetically attached to the roof surface.

- Fully adhered. In this case, The rolled or listed material is laying on an insulation layer, concrete or wooden substrates using proper adhesive agents. This installation method is the most financially expensive but is the most reliable.

- Mechanically fastened. To achieve better tightness, roofers use special non-penetrating fasteners. This installation method demonstrates maximum protection against uplifts but does not guarantee 100% protection against leaks.

- Ballasted. In this case, roofing material is covered with stone or concrete ballast, which reliably protects the roof from uplift and mechanical damage. The disadvantage of this installation method is the difficulty with possible repairs in the future. This method of installation has been used infrequently in recent years.

The installation method depends on the roof area, type of roof, chemical composition, and membrane features.

Two groups of single-layer materials exist: Thermoplastic (which becomes elastic when heated and can be sealed by heat-welding) or Thermoset (which can only be seamed with adhesives). PVC or TPO belongs to the first group, while EPDM is Thermoset.

Membrane Roofing Maintenance Tips

A professionally installed roof membrane can last up to 30 years or more with prompt inspections, maintenance, and repairs.

The thinner the layer of the roofing covering, the more frequently it is necessary to check the roof. In addition, inspect the roof after strong winds and heavy rains.

If water collects on the roof surface, remove it within 48 hours after rain. If this phenomenon repeats, you may need to renovate the roof frame.

Some roofing membrane materials are not resistant to UV rays. Under the influence of sunlight, roofing membranes lose their elasticity and begin to crack, including in the places of seam joints.

Patches or repair adhesive kits can fix membranes in a small area (up to a square foot). If the roof has taken a lot of damage, it is necessary to partially or wholly replace the damaged covering (and underlayment insulation).

Conclusion

In conclusion, roof membranes are a reliable and efficient choice for roofing systems. They offer numerous advantages, including durability, flexibility, and weather resistance, making them suitable for various applications. Whether building a new roof or replacing an old one, a roof membrane is a cost-effective solution that can provide long-lasting protection for your property. It is essential to carefully consider your specific needs and budget when choosing a roof membrane and hiring a qualified professional to ensure proper installation.

Denis is the driving force behind ID Flat Roof, a leading company in Boston specializing in flat roof repair and installation for over 20 years.

Expertise:

Denis excels in PVC, TPO, EPDM, and rubber roofing. His meticulous approach ensures quality and customer satisfaction.

Innovation:

Denis incorporates cutting-edge solutions like skylights and solar PV roofing.

Really enjoyed this update, can you make it so I get an email sent to me every time you make a fresh post?

Thank you for your enthusiasm about our posts! We’re delighted to hear that you’re finding our content valuable.