Our Сompleted Projects of PVC Roof | PVC Roof Mastery

High-Quality PVC Roof Installation at 23 St Marys Ct, Brookline, MA

ID Flat Roof recently completed a roofing upgrade at 23 St Marys Ct, Brookline, MA 02446, showcasing our commitment to delivering energy-efficient and durable roofing solutions. Under the guidance of ...

Comprehensive Roofing Renovation at 7 Craigie Circle, Cambridge, MA

ID Flat Roof recently completed a large-scale roofing project at 7 Craigie Circle, Cambridge, MA, showcasing our expertise in handling complex, high-volume roofing renovations. Under the guidance of principal contractor ...

Efficient White PVC Roof Installation at 54 Solaris Rd, Hyde Park, MA

ID Flat Roof recently completed a quick but meticulously executed roofing project at 54 Solaris Rd, Hyde Park, MA, demonstrating our efficiency in delivering high-quality roofing solutions in Boston's residential ...

Comprehensive Roof System Upgrade at 241 Columbia St, Cambridge, MA

ID Flat Roof recently completed a multifaceted roofing project at 241 Columbia St, Cambridge, MA, showcasing our ability to address complex roof system needs beyond simple membrane replacement. Under the ...

Urban Roofing with Railing Restoration at 97 Moreland St, Roxbury, MA

ID Flat Roof recently completed a specialized one-day roofing project at 97 Moreland St, Roxbury, demonstrating our ability to handle unique urban roofing challenges requiring careful attention to architectural details ...

Custom Drainage Solution Roof Project at 378 Hillside Ave, Needham Heights, MA

ID Flat Roof recently completed a specialized roofing project at 378 Hillside Ave, Needham Heights, MA, showcasing our problem-solving expertise and technical knowledge. Under the guidance of principal contractor Denis ...

Efficient Urban Roof Replacement at 6 Franklin St, Boston, MA

ID Flat Roof recently completed a small but precisely executed roofing project at 6 Franklin St, Boston, MA, demonstrating our versatility in handling projects of all sizes in Boston's dense ...

Comprehensive Dual-Roof PVC Replacement at 94 Pleasant St, Brookline, MA

ID Flat Roof recently completed a multi-faceted roofing project at 94 Pleasant St, Brookline, MA, showcasing our expertise in handling complex roofing needs. This project, led by principal contractor Denis ...

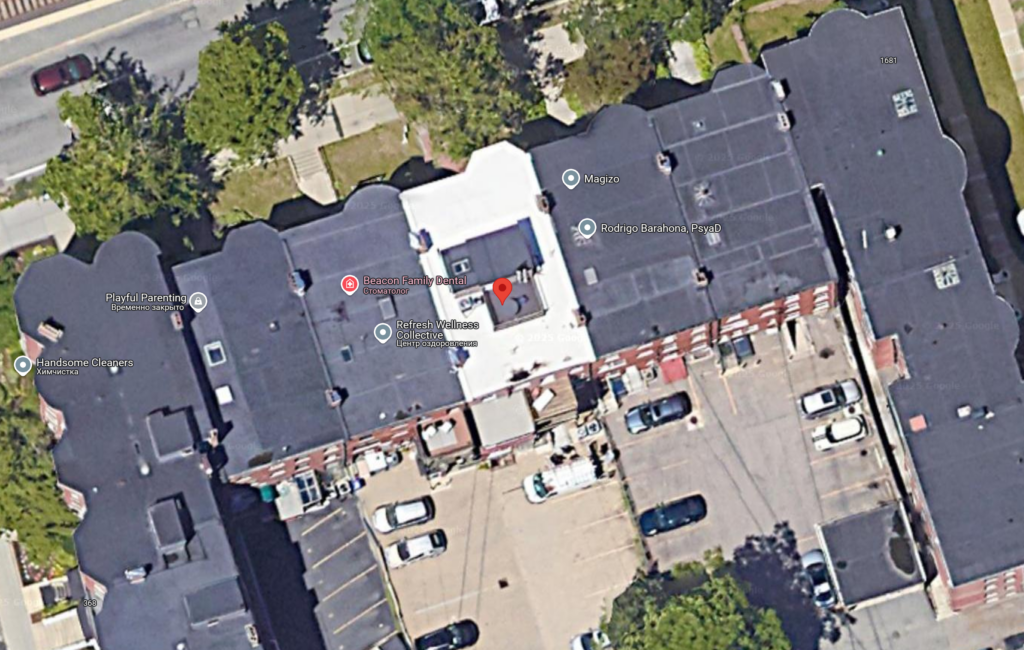

Professional PVC Roof Replacement at 1032 Commonwealth Ave, Brookline, MA

ID Flat Roof recently completed a precision roofing project at 1032 Commonwealth Ave, Brookline, MA, demonstrating our expertise in delivering efficient, high-quality roofing solutions in one of Greater Boston's bustling ...

Premium PVC Roof Installation on New Construction at 1616 Beacon St, Brookline, MA

ID Flat Roof recently completed a high-quality roofing installation for a new construction project at 1616 Beacon St, Brookline, MA. This project showcases our versatility in applying our roofing expertise ...

Successful PVC Roof Replacement at 1801 Beacon St, Brookline, MA

ID Flat Roof recently completed a high-quality roofing project at 1801 Beacon St, Brookline, MA 02445, showcasing our expertise in modern flat roofing solutions in one of Boston's most prestigious ...

Successful PVC Roof Replacement at 1689 Beacon St, Brookline, MA

ID Flat Roof recently completed a precision roofing project at 1689 Beacon St, Brookline, MA, demonstrating our expertise in delivering high-quality roofing solutions in one of Greater Boston's most distinguished ...

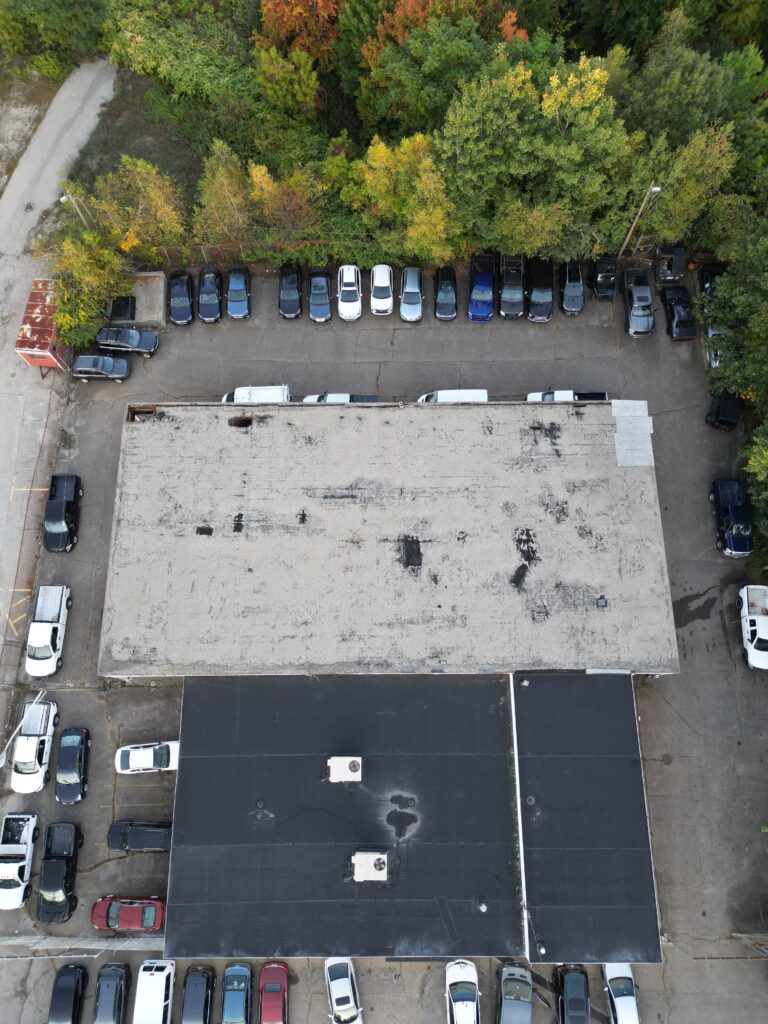

Major Commercial Roof Renovation at 1174 Kingstown Rd, South Kingstown, RI

ID Flat Roof recently completed an extensive commercial roof renovation at 1174 Kingstown Rd, South Kingstown, RI, showcasing our capability to execute large-scale, complex roofing projects beyond the Greater Boston ...

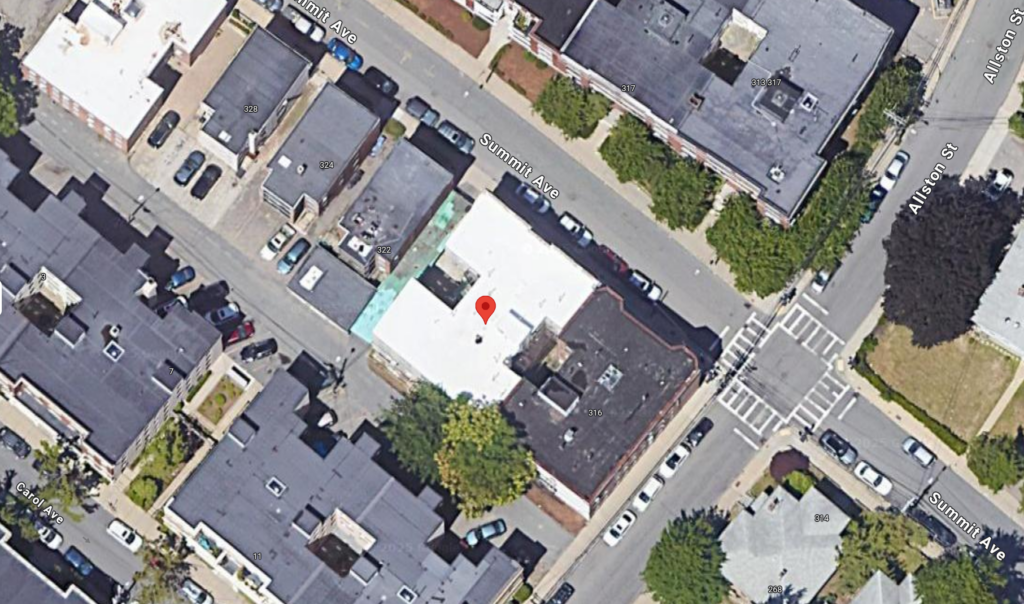

Successful PVC Roof Replacement at 318 Summit Ave, Boston, MA

ID Flat Roof recently completed a high-quality roofing project at 318 Summit Ave, Boston, MA 02135, showcasing our expertise in modern flat roofing systems. This 10-day project involved upgrading the ...

Expert Roof Replacement at 18 Dartmouth Dr, Framingham, MA

At ID Flat Roof, we take pride in delivering top-notch roofing solutions tailored to the unique needs of each project. Under the guidance of our experienced principal contractor, Denis Tchernov, ...

Carport and Roofing Project at 155 Thompson Rd, Webster, MA 01570

ID Flat Roof recently completed an impressive carport and roofing renovation at 155 Thompson Rd, Webster, MA 01570. This project exemplifies our commitment to providing high-quality, durable roofing solutions while enhancing the functionality ...

ID Flat Roof Creates a Stunning 3-Season Porch Addition in Westwood, MA

ID Flat Roof, in collaboration with general contractor Denis Tchernov, recently completed a remarkable addition project at 2 Gay Farm Way, Westwood, MA, transforming a modest porch into a luxurious ...

ID Flat Roof Completes Striking PVC Roof Installation on Castle-Like Home

ID Flat Roof was recently entrusted with a unique project: transforming the roof of a stunning, castle-like home nestled in the scenic landscapes of Milton, MA. This project exemplifies our ...

Replacing a Tar and Gravel Roof with a Modern PVC Solution in Downtown Boston

At ID Flat Roof, we recently completed an exciting roof replacement project at 161 St Botolph St., Boston. The challenge? Replacing an outdated tar and gravel roof with a sleek, ...

Successful Roof Repair at 8 Cross Street: How I Solved Flat Roof Issues with PVC

My name is Denis Tchernov, and I’m the head contractor at ID Flat Roof, a roofing company based in Massachusetts. Recently, we completed a PVC flat roof replacement Massachusetts project ...

PVC Roofing Project at 33 Dwight St, Brookline, MA: Installation Overview

The PVC roofing project at 33 Dwight St in Brookline, MA, involved completely removing and replacing the existing rubber roof. Main Contractor: Denis TchernovLocation: 33 Dwight St, Brookline, MAProject ...

Roof Replacement Project at 13 Stanhope St., Boston

ID Flat Roof expertly handled the recent PVC roof replacement project at 13 Stanhope St., led by Denis Tchernov, their chief contractor. This marks a significant improvement for the ...

Top Roofing Wayland Services for Quality Repairs & Installations

Searching for roofing services in Wayland? ID Flat Roof also offers roofing services. This article covers the expert services provided by ID Flat Roof, from roof removal to new roof ...

PVC Roof Brookline Solutions: Your Guide to Durable, Long-Lasting Protection!

Are you searching for a reliable roofing option in Brookline? PVC roof Brookline offers superior durability and weather resistance, making it a preferred choice for many Brookline residents. This guide ...

Essential Commercial Roof Repair Service Solutions for Your Business Needs

When your commercial roof needs repair, timely and professional service is essential to safeguard your property. This article will guide you through the early signs of roofing issues, how to ...

Unlocking the Durability & Cost-Effectiveness of PVC Roof Systems

As Dennis Tchernov, the leading roofer at ID Flat Roof, I'm here to explain why a PVC roofing system might be the perfect choice for your property. Known for its ...

Reimagining Spaces: ID Flat Roof’s Spectacular Home Transformation in Revere, MA

Embarking on a transformation journey, this Revere home renovation by ID Flat Roof epitomizes the blend of modern sophistication and classic charm. Welcome to our latest blog post, where we ...

Commercial Roofing Contractors in Boston and Massachusetts

ID Flat Roof is a professional contractor providing superior commercial roofing services in Boston, Newton, Cambridge, and throughout Massachusetts for over 20 years. We offer the most efficient and best-working ...

Metal Roof and PVC Roof Replacement | Needham Roofers

Looking for trusted and skilled roofers in Needham, MA? ID Flat Roof is one of the prime roofing companies in Needham, MA, with professional services and highly qualified specialists. Our ...

Floating Rooftop Deck

Flat roofs are typical for residential and commercial real estate in the US. In addition, they have various advantages that a property owner can use, like an opportunity to turn ...

PVC Membrane Installation on Shed Dormer Flat Roof Wellesley

Getting your roof in shape is a must for each homeowner. And this starts with selecting the proper roofing. When you need durable and reliable flat roofing in Wellesley, MA, ...

PVC Roof Membrane: Modern Solution for Flat and Low-Slope Roofs in Wayland

PVC Roof Membrane is one of the best flat roof materials ever invented by humanity. A PVC membrane is a durable, sealed, single-layered synthetic material in white or other colors ...

PVC Low Pitch Roof Installation Newton

Without a doubt, Newton, MA, is one of the best cities close to Boston if you’re looking for a quiet, family-friendly area with good neighbors and a restful atmosphere. And ...

Metal Shingle and PVC Roof Installation Milton

Did you know the roof is the #1 protector of your home? Roofs protect us from the weather and create a cozy home space. Their integrity is crucial for every ...

PVC Flat Roof Installation – Roofing Contractors Lexington MA

Flat roofs are an indispensable part of construction for various architectural styles. It is essential to use that type of roofing for commercial buildings, high-rise constructions, and private houses designed ...

PVC Flat Roof Installation Lincoln | ID Flat Roof

Today, when building a house, architects and engineers often prefer a flat roof to other types of roofing. This option not only allows you to save on building materials and ...

Shed Dormers Roofing: How to Choose and What to Do With It

The ability to expand the space of your home is invaluable. For many families, the problem of increasing usable living space is particularly acute. If you have children, you need ...

PVC Weston, MA, Roofing Repairs and Installation

Before a PVC roof membrane installation, it is necessary to install any insulation board. We use EPS foam or ISO insulation during Weston roofing repairs in Massachusetts. These two insulation ...

Lenox, MA, Roofing Services by ID Flat Roof

The matter of choice among roofing contractors in Lenox, MA, often becomes a real headache for homeowners. Our company has been in business since 2000, building a strong reputation in ...

Flat Roof Installation Lynn | ID Flat Roof, MA

Flat Roofing Lynn MA has long ceased to be the choice of only administrative buildings and multi-unit condominiums. Today, many owners choose this type of roof for private houses because ...