All You Need to Know about Commercial Flat Roofing

Reading Time: 4 minutesMost commercial buildings, from massive warehouses and factories to hotels and small shops, have a flat roof. The reasons for the widespread use of commercial flat roofing are apparent. Provided the correct choice of materials and professional installation, a flat roof reliably protects the building from leaks and requires almost no maintenance. Let’s look at several popular materials roofing contractors use in the US while installing new and renovating old flat roofs.

This article uses statistics from the Manual of Low-Slope Roof Systems by R.L. (Dick) Fricklas and C.W. Griffin. Even though the book was written almost 50 years ago, it remains one of the best desk books for those specializing in flat roofing.

Commercial Flat Roofing: 3 Important Questions to Ask

There is no universal material that would suit every commercial facility.

So, before you make your final choice, please answer three critical questions. The first question is, what qualities and advantages should the roofing material have? Increased strength, flexibility, low cost, ease of installation, or something else. The second question is, what installation method will ensure the safe and durable operation of the roof? Fully adhered, mechanical, or ballasted. Third, how often can you maintain your roof, taking into account roof foot traffic, rainfall, and wind load? One a year or less often.

Essential Roofing Selection and Maintenance Queries

Long story short, if you answer all three questions correctly before getting your roof repaired, installed, or renovated, a commercial roof will become a reliable protection from any weather conditions, the atmosphere inside the building will remain comfortable all year around, and you will not think about roof repairs for at least 10-20 years.

Commercial Flat Roofing: Some Statistics

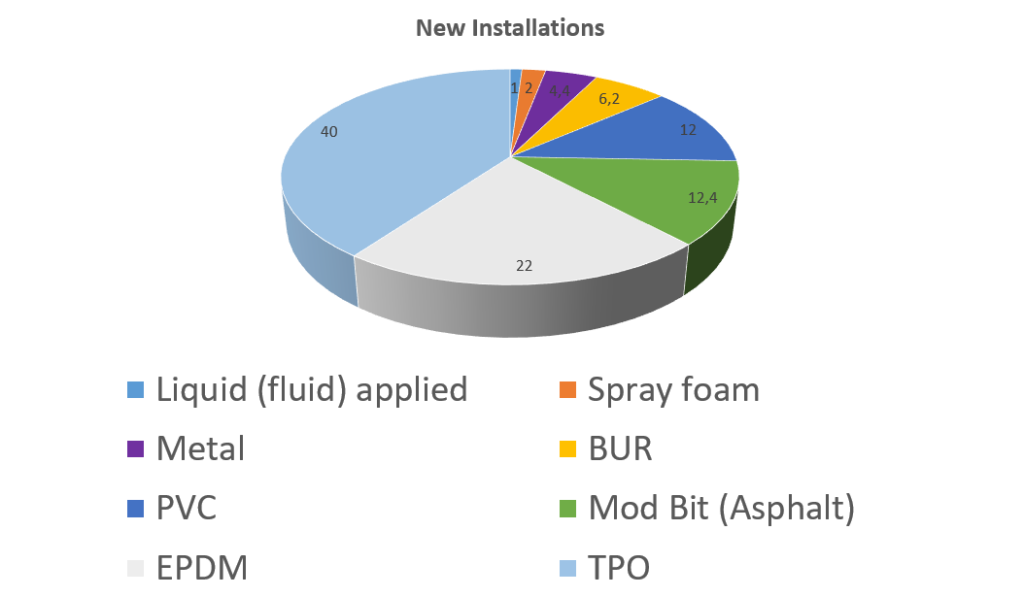

Firstly, let’s talk about types of commercial flat roofing installed from scratch in the US. The most popular materials in this category are polymer membranes – EPDM and TPO. Almost two-thirds of all new roofs are installed using these materials. Third place in the statistics is shared by time-tested technology – modified bitumen and PVC. BUR (built-up) technology is considered obsolete and is used rarely. Metal roofs also cannot be called super popular due to the high cost of materials.

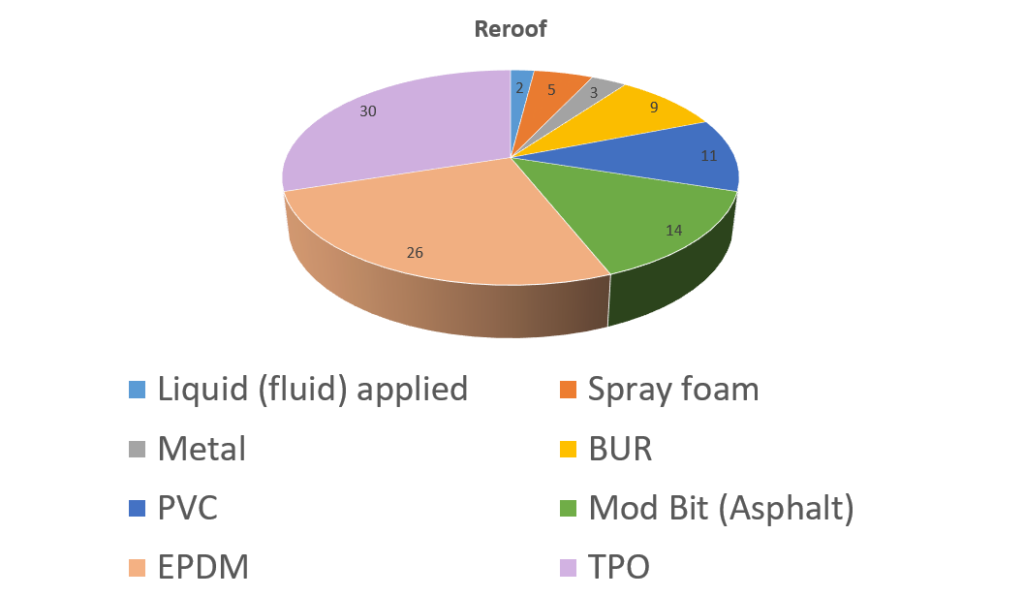

The statistics are also similar in the category of renovated commercial roofs. The first places in the demand rating are TPO and EPDM. Every fourth roof is covered with modified bitumen or PVC during the renovation process. As with new roofs, BUR technology is rarely used, but some still choose old-school technology instead of innovative commercial flat roofing systems, just like tar and gravel roofs.

Single-ply membrane: TPO or EPDM

Two types of membranes are used as roofing for commercial properties. These are thermoset (EPDM or ethylene propylene diene monomer) and thermoplastic membranes (TPO and PVC). These types of roofs are supposed to be innovative, but membranes were invented a long time ago.

EPDM roofing is a time-tested material that (if professionally installed) provides almost 100% protection against leaks. In addition, rubber roofing is resistant to a wide range of chemicals.

PVC and TPO membranes differ from rubber roofing in their physical and operational features, but the main difference is that they remain hard until heated. But they are resistant to leaks, too. Several ways to install TPO and PVC membranes include adhering, ballasting, and attaching them with special fasteners.

One of the critical advantages of membranes is that they are available in several colors, including light shades. Such a white membrane roof heats up less, so you spend less on cooling and air conditioning.

Asphalt or so-called Mod Bit

Another technology that was very popular in the past is modified bitumen. Mod-bit flat roofing materials consist of a layer of asphalt applied to reinforced sheet material. In addition, various components (APP and SBS) are added to the coating to increase its waterproofness and flexibility.

In the case of asphalt commercial roofs, several types of installation are used – using hot asphalt and heat welded technology, hot mopping, or torching.

Commercial flat roofing: BUR

BUR is a well-known technology that roofers have used for over 80 years. The built-up roofing system is made from roofing felts, which are reinforced and joined with bitumen. One of the critical features of BUR is the several-layer structure. Despite the excellent tightness, this technology is considered outdated since it is not environmentally friendly, and installing such a roof is time-consuming and requires much more effort.

Metal

Metal is one of the best highly durable materials ever invented by mankind. However, metal roofing systems are not the best choice for every commercial property. Firstly, due to the high cost. Secondly, because the metal heats up under the sun, steel, even if polymer coatings protect it, is susceptible to corrosion.

On the other hand, if installed correctly, metal is eternal and reliably protects buildings against rain and hail.

Other options

The part of these roofs in the American commercial real estate market does not exceed a few percent, but they can also be seen on new buildings built in the last 10-15 years.

Firstly, these are the so-called green roofs, with plants, shrubs, and even trees planted on the surface. Unlike green roofs for residential properties, commercial roofs have living plants planted in tray systems. In addition, the green flat roofing system includes a unique drainage system. But such a roof is the most environmentally friendly.

Secondly, these are roofs with solar panels. Solar panels are a trend for residential roofs, but many offices and hotels also install solar panels to save on energy bills, at least during the summer months.

Cost-Effective Solutions for Your Commercial Flat Roof

Conclusion: study the offers and consult with experts

The service life and reliability of the roof directly depend on the correct choice of materials and installation method. However, each material has its characteristics, advantages, and disadvantages. In addition, the material for a new roof or renovation should be selected considering many factors like the climate in the region, the area, and the facility’s architectural features.

We recommend consulting with a local roofing contractor who will review your project and requirements to suggest the best options to fit your budget.

Denis is the driving force behind ID Flat Roof, a leading company in Boston specializing in flat roof repair and installation for over 20 years.

Expertise:

Denis excels in PVC, TPO, EPDM, and rubber roofing. His meticulous approach ensures quality and customer satisfaction.

Innovation:

Denis incorporates cutting-edge solutions like skylights and solar PV roofing.